Basic RV Furnace 101

Planning on an RV trip this spring? You will want to make sure your furnace will keep you cozy.

Although the RV camping season is approaching, some folks like to get an even earlier start then the traditional May long weekend and chances are you’re going to need your RV furnace to provide warmth for a more comfortable stay. Your first trip of the season will be very disappointing—and cold—without a properly operating heating system and it is not an option to use your cooktop or oven to provide comfort heat to the interior.

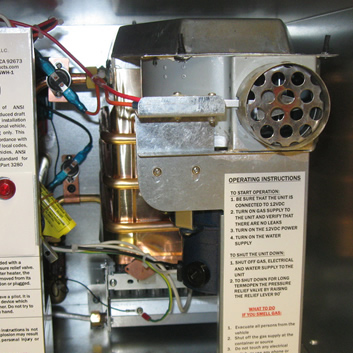

Your RV furnace needs four requirements met to ensure proper operation and efficient heating. The first system requirement is proper LPG supply and a gas pressure of 11" of water column. A near empty propane tank or lack of sufficient pressure will cause the furnace to work intermittently or shut down.

Secondly, the voltage provided must be between 10.6 and 13.5 volts. Low voltage is a common cause of failure to ignite as the fan speed will not be sufficient to close the sail switch in the circuit.

Thirdly, the ducting requirements requested by the manufacturer of the furnace must be met by the installer. If there are not enough ducts, or obstructions like mats or trash cans are blocking air flow, the furnace may develop a limiting or cycling problem. This will cause the burner to work erratically during each heat cycle.

The fourth requirement is the furnace will need the proper amount of return air, which is determined by the manufacturer with regards to the size of the furnace. Again this area needs to be clean and free from obstructions.

Basically the sequence of operation is similar with both of the main manufacturers, namely Atwood and Suburban.

It all starts with the thermostat being turned on and the desired temperature set. When the room temperature falls below the set point, a signal is sent to the fan relay located near or on the circuit board and the fan motor will start. One side of the motor shaft has an air circulation wheel and the other side has a combustion wheel to provide air to the burner. Normally, circulation air will blow against the sail switch. With at least 70 per cent air flow being provided, the limit or high temperature safety switch will then provide power to the DSI or Direct Spark Ignition board. The burner or heat chamber will be purged followed by the gas valve opening and a high voltage spark sent to the igniter to light the burner and heat the RV to the desired temperature. After the temperature is reached the ignition system will shut down and the blower motor will continue to run until the relay opens and shuts the furnace down. Again, this is a very basic description to help you understand the proper operation of your RV furnace.

If your furnace burner seems to shut down and relight during a heat cycle it may have a limiting condition or sooting at the outside exhaust vent, which can create carbon monoxide that could enter the RV. Both of these conditions should be checked out at your local RV service dealership by a certified RV technician.

Lastly, the use of aftermarket screens to cover the outside vent area should be avoided. This will restrict the exhaust and intake air resulting in improper burner operation and a potentially unsafe condition.

Your RV furnace is probably the appliance that gets used the least in comparison to the water heater, fridge or stove. A pre-trip inspection or professional service check annually will ensure proper operation when you need it the most.